WATER WASH SYSTEM

The water wash system is designed to remove grease and contaminants from the canopies interior keeping daily maintenance to a minimum.

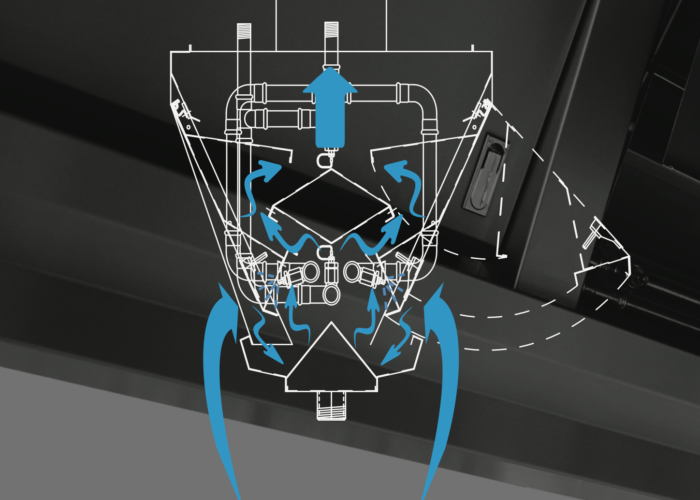

In place of conventional filters the grease particles in the canopy are separated by a specially designed labyrinth.

The air moves through the canopy at a high speed and is forced to make a series of turns around the labyrinth throwing the grease out of the airstream by a centrifugal force. The extracted grease is collected in the trough. The wash cycle can be automatically or manually activated.

Hot water and detergent is sprayed into the canopy for a preprogramed time from a control cabinet which regulates the dosage of the detergent required to clean the system. A high standard of hygiene is maintained and the installation is better protected against the build-up of grease deposits which constitute a fire hazard. To further reduce fire hazards we recommend a fire protection system (optional) to be integrated into the system.

For areas where stringent environmental regulations are in force, the water wash systems are an excellent choice, combined with our grease shield.

ADVANTAGES

High grease removal rate ensures high level of hygiene

Reduces the risk of fire

Constant air pressure drop over the canopy

System efficiency does not depend on reliance of cleaning staff Requires minimum maintenance

Comfortable working climate

CONSTRUCTION

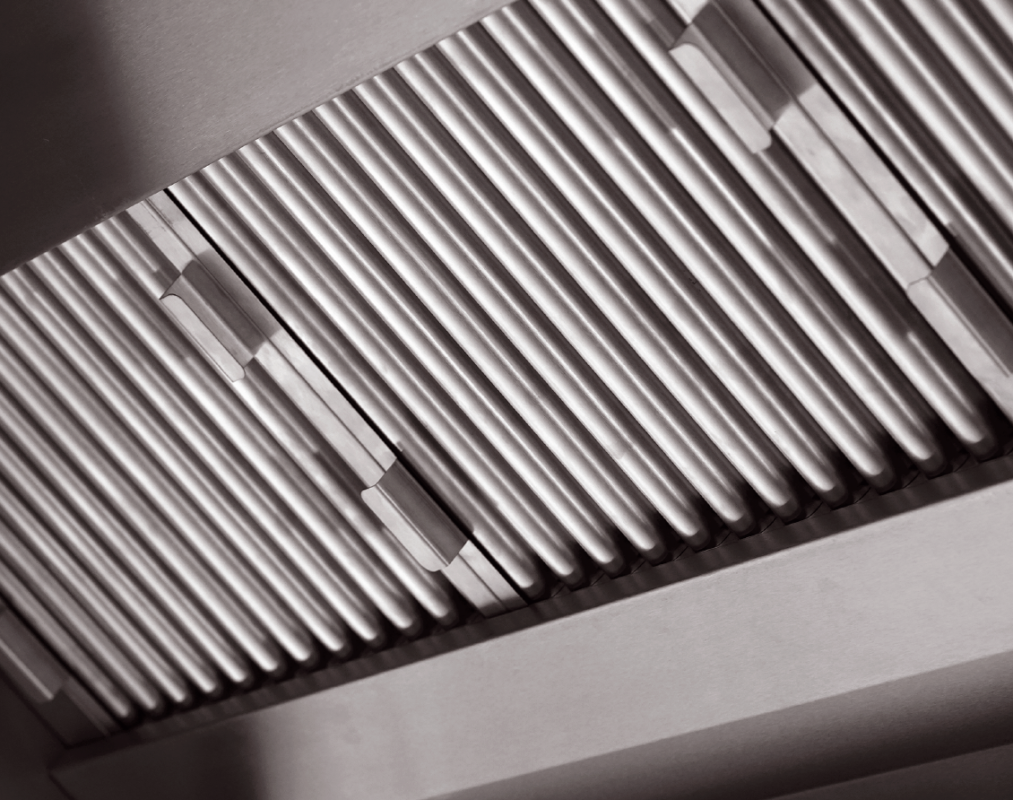

The SSS-India water wash baffles are fully welded 1.0 – 1.2mm thick type 304 stainless steel assemblies. Grease collection channels run the full length of the canopy.

Full length hinged access panels mounted with gas filled dampers and locked with captive quick release fastenings allows for easy access to the plenum interior, the water pipework and spray nozzles for inspection purposes.

The control panel is fabricated in type 304 stainless steel and measures 800 x 800 x 250mm and is secured by a lock. A tank containing detergent is housed within the panel which also features a digital display to monitor the system.

A main hot water feed is required (to be provided by others) to a 3⁄4” water connection.

The recommended minimum water supply temperature is 70° and maximum of 4°dH water hardness.

Water usage for wall and island canopies is approximately 1.75 L/min/m.

Optional – V-DPS Drainage Pump System

The drainage pump system extends the canopy length by 300mm when a direct sewer connection is not possible. The water is pumped to a sewer connection located up to 5 meters from the canopy.

JET STREAM AIR TECHNOLOGY

Jet Stream Air is drawn by fan from the ceiling void or via ducts to factory fitted flanges on top of the canopy. The air passes into the insulated supply air plenum and passes out through a series of slots into the main canopy envelope.

The air is delivered from these slots at a maximum velocity of 2m1/s and represents less than 10% of the

total extract air flow rate.

This technology ensures a positive capture and containment of the thermal plume generated by the cooking process.

All Vianen canopies are available with several options to further increase their efficiency safety and improve the air-quality.