DESCRIPTION

Suitable for all types of cooking equipment over wall and island arrangements.

A significant improvement of the capture and containment performance of the Vianergy II® canopy is obtained due to the modification in the curved structure on the internal side of the front of the canopy.

The curved structure ends with a specially designed (and patented) lip, angled upward to turn the deflected air back to the filter.

The canopy is designed with slots for the air supply, capture air principle, on the inner bottom circumference – three sides (wall type) and 4 sides (island type).

This capture air is introduced into the canopy with a maximum velocity of 2m1/s and it lifts the deflected airflow back to the filter bank, avoiding spillage of fumes and contaminants back into the kitchen.

A significant energy saving, up to 28%, is achieved due to this new, patented construction, tested by an independent institute in the Netherlands, conform ASTM F1704 method.

ADVANTAGES

Energy saving – reduction in air conditioning up to 28%

Clever space saving due to reduction in fans and duct sizing

Reduction in size of air treatment unit

Reduction of kW consumption

Reduction in required air change rate per hour

Jetstream technology reduces spillage of exhaust fumes into the kitchen area Reduces draught in the kitchen

Comfortable working climate

FECON® filters – UL and NSF certified

FECON® filters – tested and approved flame retardant by an independent institute.

CONSTRUCTION

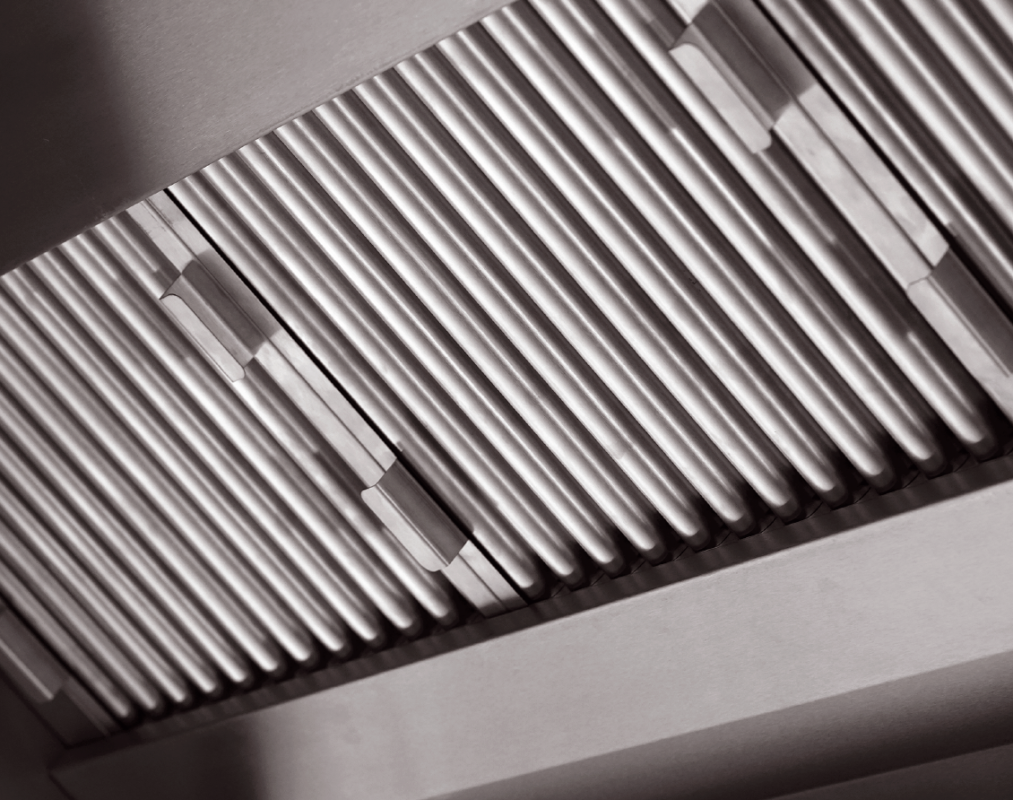

The canopy is fabricated from 1.0 – 1.2mm thick type AISI 304 or optional AISI 316L stainless steel. All visible surfaces are ultra- ne grain polished (320 grit) and polythene protected.

The canopy is cut, punched and folded into seamless section of up to 6m in length and factory assembled by means of seam welds and non-visible mechanical fixings.

Joints are provided with internal cover-plates so that no joints or mechanical fixings are visible. All metal edges are rolled smooth and are free from sharp edges and projections.

The canopy is equipped with SSS FECON® grease extraction filters which are designed to allow the grease to run off the filters into an integral grease collecting channel and then into easily removable grease trays.

The Vianergy II® canopy has a constant exhaust pressure drop of 100 Pa.

JET STREAM AIR TECHNOLOGY

Jet Stream Air is drawn by fan from the ceiling void or via ducts to factory fitted flanges on top of the canopy. The air passes into the insulated supply air plenum and passes out through a series of slots into the main canopy envelope.

The air is delivered from these slots at a maximum velocity of 2m1/s and represents less than 10% of the

total extract air flow rate.

This technology ensures a positive capture and containment of the thermal plume generated by the cooking process.

All SSS canopies are available with several options to further increase their efficiency safety and improve the air-quality.